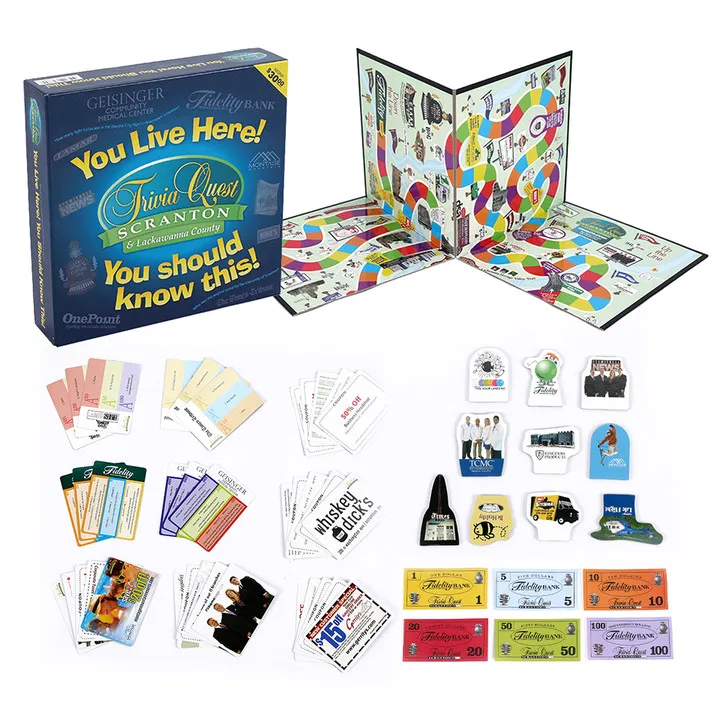

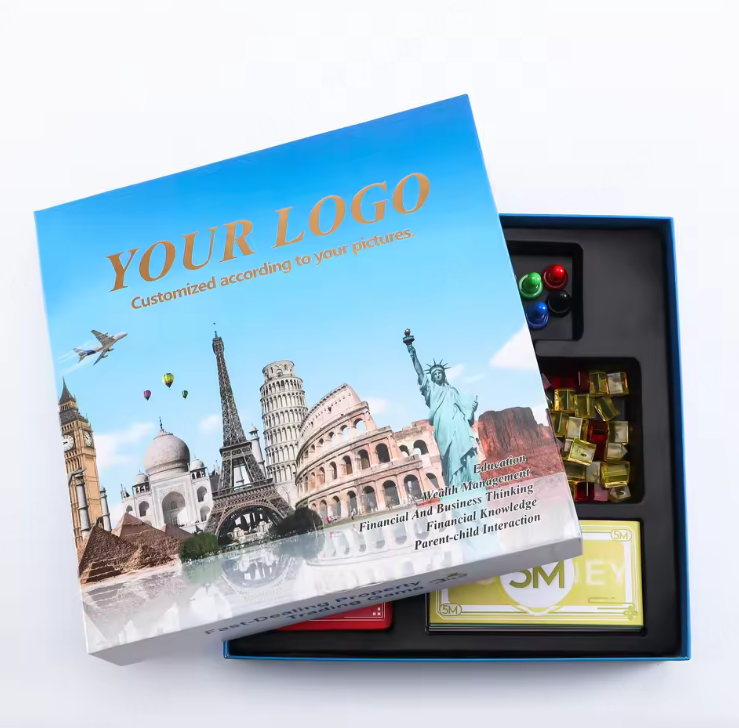

tabletop game maker

A tabletop game maker represents an innovative solution for creative individuals and businesses seeking to transform their game concepts into physical reality. This cutting-edge technology combines precision engineering with user-friendly design to facilitate the production of professional-quality board games, card games, and other tabletop entertainment products. The tabletop game maker serves as a comprehensive manufacturing platform that streamlines the entire production process from initial design to finished product delivery. Modern tabletop game maker systems incorporate advanced printing capabilities, precision cutting mechanisms, and automated assembly features that ensure consistent quality across all produced items. The technological foundation of these systems relies on digital printing technology, computer-controlled cutting tools, and intelligent material handling systems that work in seamless coordination. Users can input their game designs through intuitive software interfaces that translate creative visions into precise manufacturing instructions. The tabletop game maker processes various materials including cardstock, plastic components, wooden pieces, and specialized gaming materials to create diverse game elements. Advanced models feature multi-station operations that simultaneously handle different production tasks, significantly reducing manufacturing time while maintaining exceptional quality standards. The integration of smart sensors and quality control systems ensures that every component meets stringent specifications before final assembly. These machines support both small-scale prototyping and medium-scale production runs, making them ideal for independent game designers, small publishing companies, and educational institutions. The tabletop game maker technology represents a paradigm shift in game manufacturing, democratizing access to professional production capabilities that were previously available only to large-scale manufacturers. This accessibility empowers creative individuals to bring their unique game concepts to market without requiring substantial capital investment in traditional manufacturing infrastructure.