The journey from a brilliant game concept to a professionally manufactured custom board game represents one of the most rewarding creative endeavors in the entertainment industry. Whether you're an independent designer seeking to bring your vision to life or an entrepreneur planning to enter the lucrative tabletop gaming market, understanding the comprehensive production process is essential for success. Modern manufacturing capabilities have democratized game creation, making it possible for creators of all sizes to produce high-quality games that rival those from major publishers.

Planning Your Custom Board Game Design

Conceptual Development and Game Mechanics

The foundation of any successful custom board game begins with a solid conceptual framework that balances creativity with playability. Your initial concept should clearly define the target audience, gameplay duration, and core mechanics that will drive player engagement throughout the experience. Consider whether your game will focus on strategy, cooperation, competition, or a hybrid approach that combines multiple elements to create unique gameplay dynamics.

Game mechanics form the structural backbone of your design, determining how players interact with components and progress toward victory conditions. Popular mechanics include worker placement, deck building, area control, and resource management, each offering distinct advantages for different types of gaming experiences. The key is selecting mechanics that naturally support your theme while providing meaningful decision-making opportunities that keep players engaged from start to finish.

Component Specification and Material Selection

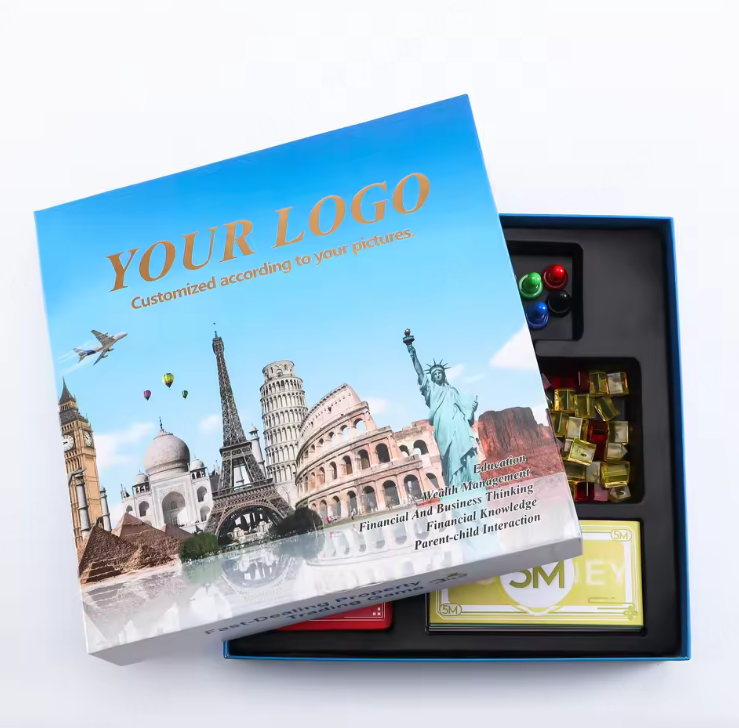

Determining the exact components required for your custom board game involves careful consideration of functionality, aesthetics, and production costs. Standard components include game boards, cards, tokens, dice, and player pieces, but innovative designs may require specialized elements such as custom molds, unique card shapes, or interactive electronic components. Each component choice impacts both the manufacturing complexity and final retail price of your finished product.

Material selection significantly influences the perceived quality and durability of your game, affecting customer satisfaction and long-term market success. Premium materials such as linen-finished cards, thick cardboard tokens, and wooden components create a tactile experience that justifies higher price points, while cost-effective alternatives can make your game accessible to broader markets without sacrificing essential functionality.

Prototyping and Testing Phases

Creating Functional Prototypes

The prototyping phase transforms your conceptual design into tangible components that allow for hands-on testing and refinement. Initial prototypes can be created using simple materials such as cardstock, printed paper, and basic tokens, focusing on functionality rather than aesthetic appeal. This approach enables rapid iteration and cost-effective testing of core gameplay mechanics before investing in higher-quality prototype materials.

As your design stabilizes through testing feedback, invest in progressively higher-quality prototypes that more closely resemble your intended final product. Professional prototype services can produce near-production-quality components that provide accurate representations of how your custom board game will feel and function when manufactured at scale, helping identify potential issues before committing to full production runs.

Comprehensive Playtesting Strategies

Systematic playtesting represents the most critical phase of custom board game development, providing essential data about player behavior, game balance, and overall enjoyment factors. Begin with closed testing sessions involving friends and family to identify obvious design flaws and mechanical issues, then expand to blind playtesting with unfamiliar groups who can provide unbiased feedback about rule clarity and gameplay flow.

Document all feedback systematically, tracking specific issues such as game length variations, rule ambiguities, and balance problems that emerge across multiple sessions. Professional game design often requires dozens of playtesting iterations to achieve optimal balance, so maintain detailed records of changes and their impacts on gameplay to avoid reverting successful modifications during the refinement process.

Manufacturing Process Overview

Selecting Production Partners

Choosing the right manufacturing partner determines the quality, timeline, and cost-effectiveness of your custom board game production. Research potential manufacturers thoroughly, examining their previous work samples, production capabilities, and client testimonials to ensure they can meet your specific requirements. Consider factors such as minimum order quantities, lead times, quality control processes, and communication responsiveness when evaluating potential partners.

International manufacturers often provide cost advantages for larger print runs, while domestic producers may offer faster turnaround times and easier communication for smaller quantities. Request detailed quotes from multiple manufacturers, ensuring all specifications are clearly communicated to enable accurate cost comparisons and timeline estimates for your project.

Quality Control and Production Monitoring

Implementing robust quality control measures throughout the production process protects your investment and ensures customer satisfaction with the final product. Establish clear quality standards for all components, including color accuracy, cutting precision, and material consistency, then work with your manufacturer to create inspection protocols that verify these standards at key production milestones.

Regular communication with your production team enables proactive problem-solving and prevents minor issues from becoming major delays or quality compromises. Request production samples at various stages to verify that manufacturing processes are meeting your specifications, and be prepared to make adjustments if quality issues emerge during production runs.

Cost Analysis and Budget Planning

Understanding Production Cost Factors

Accurate cost analysis for custom board game production requires detailed understanding of how various factors influence manufacturing expenses. Component complexity, material choices, print quantities, and manufacturing location all significantly impact per-unit costs, with economies of scale typically reducing expenses for larger production runs. Specialized components such as custom dice, unique card shapes, or premium materials command higher prices but may justify increased costs through enhanced player experience and market differentiation.

Hidden costs often emerge during production, including tooling fees for custom components, shipping expenses, import duties, and quality control inspections. Factor these additional expenses into your budget planning to avoid financial surprises that could derail your production timeline or force unwanted compromises in component quality or game functionality.

Funding and Financial Strategy

Securing adequate funding for custom board game production requires careful financial planning and may involve multiple funding sources depending on your production scale and market strategy. Self-funding provides maximum creative control but limits production quantities, while crowdfunding platforms enable larger print runs but require successful marketing campaigns and community engagement to reach funding goals.

Publisher partnerships offer professional marketing support and established distribution networks but typically involve revenue sharing and reduced creative control over final product decisions. Evaluate funding options based on your long-term goals, risk tolerance, and desired level of involvement in marketing and distribution activities for your finished game.

Marketing and Distribution Strategies

Building Pre-Launch Awareness

Successful custom board game marketing begins months before production completion, building anticipation and community engagement through strategic content creation and social media presence. Develop compelling visual materials showcasing your game's unique features, components, and gameplay elements, then share development progress through blog posts, videos, and social media updates that invite community participation in the creative process.

Engage with existing board gaming communities through forums, conventions, and online groups to build relationships with potential customers and gather valuable market feedback. Influencer partnerships with board game reviewers and content creators can significantly expand your reach and provide credible endorsements that drive pre-orders and launch success.

Distribution Channel Selection

Modern distribution options for custom board games range from direct-to-consumer sales through personal websites to partnerships with established retail networks and online marketplaces. Each channel offers distinct advantages and challenges, requiring careful consideration of your target market, profit margins, and available resources for order fulfillment and customer service.

Direct sales provide maximum profit margins and customer relationship control but require significant investment in marketing, order processing, and shipping logistics. Retail partnerships offer broader market reach and professional distribution infrastructure but typically involve lower profit margins and reduced control over pricing and promotional strategies.

FAQ

How long does custom board game production typically take

The complete timeline for custom board game production varies significantly based on complexity, quantity, and manufacturing location, typically ranging from 6 to 16 weeks from final artwork approval to finished product delivery. Factors influencing production time include component complexity, printing queue schedules, quality control requirements, and shipping logistics. International manufacturing may extend timelines due to customs processing and extended shipping durations, while domestic production often provides faster turnaround but at potentially higher per-unit costs.

What minimum order quantities should I expect for professional manufacturing

Most professional board game manufacturers require minimum order quantities between 500 and 3000 units, depending on component complexity and production methods. Simple games with standard components may have lower minimums, while complex games requiring custom tooling or specialized materials typically demand higher minimum orders to justify setup costs. Some manufacturers offer lower-quantity options for prototype or test market runs, though per-unit costs will be significantly higher than full production pricing.

How do I protect my game design during the production process

Protecting intellectual property during custom board game production involves multiple strategies including non-disclosure agreements with manufacturers, trademark registration for game names and logos, and copyright protection for original artwork and written materials. While game mechanics themselves cannot be copyrighted, unique implementations and creative expressions can receive protection. Work with intellectual property attorneys familiar with gaming industry practices to develop comprehensive protection strategies appropriate for your specific game and market goals.

What factors most significantly impact custom board game production costs

Production quantity represents the most significant cost factor, with per-unit expenses decreasing substantially as order quantities increase due to fixed setup costs being distributed across more units. Component complexity, material quality, and manufacturing location also heavily influence costs, while specialized features such as custom dice, unique card shapes, or premium finishes command premium pricing. Balancing quality aspirations with market pricing constraints requires careful component selection and strategic compromise between ideal design vision and commercial viability.