The board game industry has experienced tremendous growth over the past decade, with global market revenues reaching new heights annually. For entrepreneurs and established companies looking to enter this lucrative market, understanding the intricacies of working with a professional board game manufacturer is crucial for success. Manufacturing costs represent one of the most significant factors in determining profitability, market positioning, and long-term sustainability of any tabletop gaming venture.

Production expenses vary dramatically depending on game complexity, component quality, order quantities, and manufacturing location. A comprehensive understanding of these variables enables informed decision-making throughout the development process. From initial prototyping to full-scale production runs, each phase presents unique cost considerations that directly impact final retail pricing and market competitiveness.

Modern manufacturing facilities offer diverse production capabilities ranging from simple card games to elaborate miniature-heavy productions. The choice of manufacturing partner significantly influences both upfront investment requirements and ongoing operational expenses. Strategic planning around these costs ensures optimal resource allocation and maximizes return on investment for game publishers of all sizes.

Understanding Manufacturing Cost Components

Material and Component Expenses

Raw material costs constitute the foundation of any manufacturing budget, with paper quality, cardboard thickness, and plastic grades directly affecting both expenses and final product quality. Premium materials command higher prices but often justify the investment through enhanced durability and consumer appeal. Standard game boards typically utilize 1.5mm to 2.5mm cardboard, while deluxe editions may incorporate thicker substrates or specialized finishes.

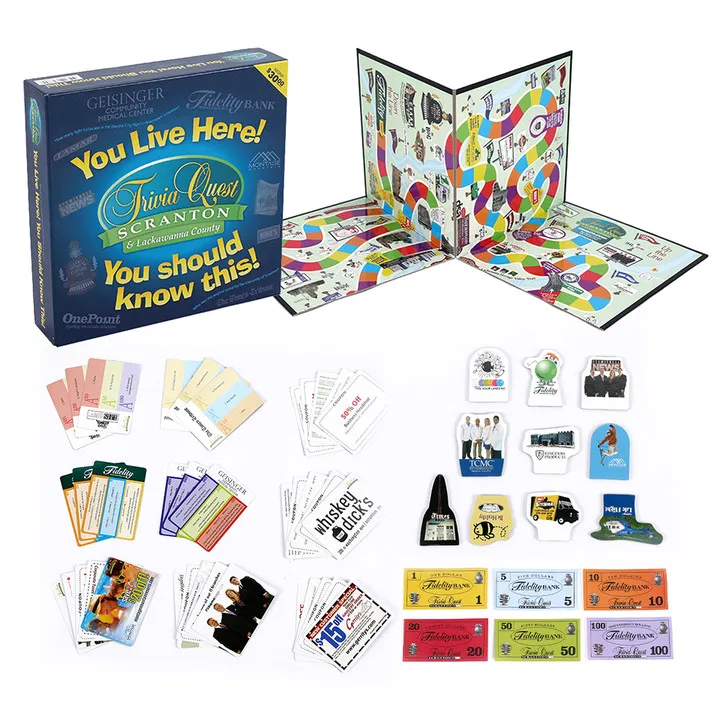

Component complexity significantly impacts material expenses, with custom-shaped pieces, multiple card decks, and specialized tokens requiring additional manufacturing processes. Plastic components generally cost more than cardboard alternatives but offer superior longevity and perceived value. Wooden pieces represent the premium option, often doubling or tripling material costs compared to standard alternatives while providing exceptional tactile appeal.

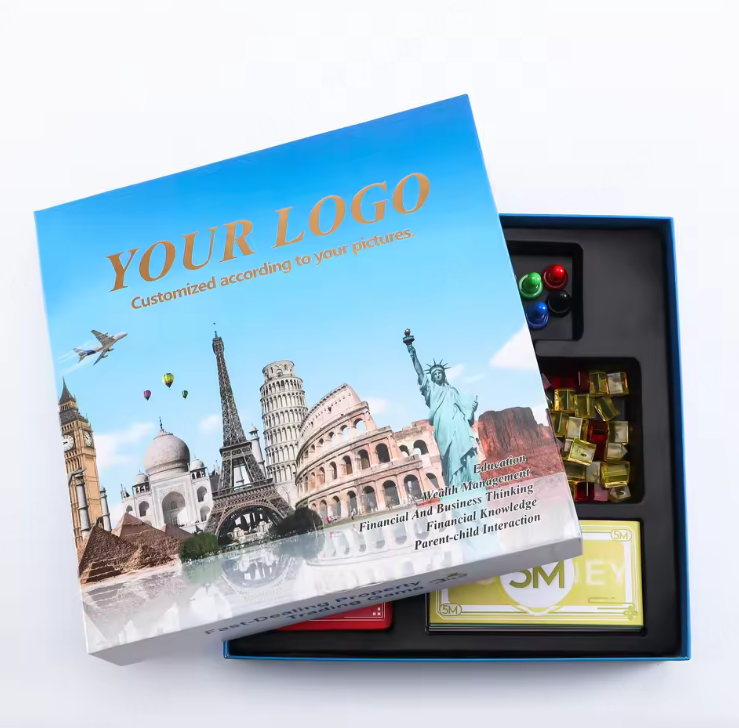

Packaging materials also contribute substantially to overall expenses, with box construction, insert design, and protective wrapping all influencing final costs. Sturdy packaging protects products during shipping while serving as crucial marketing tools at retail locations. Investment in quality packaging often generates positive returns through reduced damage rates and enhanced shelf presence.

Labor and Production Overhead

Manufacturing labor represents a significant cost component that varies considerably between production locations and facility sophistication levels. Automated production lines reduce per-unit labor costs but require higher minimum order quantities to achieve economic efficiency. Hand-assembly processes offer greater flexibility for smaller runs but increase per-unit expenses substantially.

Quality control procedures add necessary overhead expenses but prevent costly recalls and reputation damage. Experienced facilities implement multi-stage inspection processes that identify defects early in production, minimizing waste and ensuring consistent quality standards. These quality assurance measures typically add five to ten percent to base production costs but provide essential protection against manufacturing defects.

Facility overhead costs including utilities, equipment maintenance, and administrative expenses are distributed across all production runs. Established manufacturers with efficient operations typically offer better overhead allocation ratios, resulting in more competitive pricing for clients. Newer facilities may have higher overhead ratios as they establish operational efficiency and build production volume.

Quantity Discounts and Order Economics

Minimum Order Requirements

Most professional manufacturing facilities establish minimum order quantities that reflect their operational efficiency thresholds and setup cost recovery requirements. These minimums typically range from 500 to 5000 units depending on game complexity and manufacturer capabilities. Understanding these requirements helps publishers plan initial production runs and budget accordingly for market entry strategies.

Setup costs for new products include tooling preparation, color calibration, and quality standard establishment, expenses that manufacturers amortize across entire production runs. Larger orders distribute these fixed costs over more units, resulting in lower per-unit pricing. Publishers must balance inventory investment against per-unit savings when determining optimal order quantities.

Some manufacturers offer flexibility in minimum quantities for established clients or premium pricing tiers. Building strong relationships with production partners often enables access to more favorable terms and greater accommodation for varying order sizes. Long-term partnerships frequently result in preferential treatment during busy production periods and priority scheduling for urgent orders.

Volume Pricing Structures

Manufacturing economics strongly favor larger production runs, with per-unit costs typically decreasing by twenty to forty percent between minimum and maximum quantity tiers. These savings result from improved material purchasing power, reduced setup time per unit, and enhanced production line efficiency. Publishers must carefully evaluate storage costs, cash flow implications, and market demand when selecting production quantities.

Tiered pricing structures reward larger commitments while providing options for various budget levels and market strategies. Understanding these tiers enables strategic planning around production schedules and inventory management. Some publishers coordinate with distributors or retailers to aggregate orders and achieve better pricing tiers through combined volumes.

Annual volume commitments sometimes unlock additional discounts and priority production scheduling. These arrangements work well for publishers with predictable demand patterns and sufficient capital resources to support larger inventory investments. Careful market analysis and sales forecasting become crucial when committing to substantial volume agreements with manufacturing partners.

Geographic Manufacturing Considerations

Domestic versus International Production

Geographic location significantly impacts manufacturing costs, with labor rates, material availability, and shipping expenses varying substantially between regions. Domestic production often provides superior communication, faster turnaround times, and reduced shipping costs but typically commands premium pricing compared to international alternatives. Quality standards and intellectual property protection may also favor domestic manufacturing relationships.

International manufacturing, particularly in established production centers, offers substantial cost advantages for larger production runs. However, longer lead times, communication challenges, and shipping complexities require careful planning and experienced logistics management. Currency fluctuations can also impact costs significantly, necessitating careful contract structuring and risk management strategies.

Hybrid approaches combining international manufacturing with domestic fulfillment sometimes provide optimal cost-benefit combinations. This strategy leverages international production economics while maintaining domestic inventory for rapid order fulfillment and customer service. Successful implementation requires sophisticated supply chain management and inventory planning capabilities.

Working with an experienced board game manufacturer streamlines the production process and helps navigate complex international logistics requirements. Established manufacturers provide valuable expertise in material sourcing, quality control, and shipping coordination that proves invaluable for first-time publishers.

Shipping and Logistics Costs

Transportation expenses represent substantial portions of total manufacturing costs, particularly for international production arrangements. Ocean freight provides the most economical option for large shipments but requires longer planning horizons and careful coordination with production schedules. Air freight offers speed advantages but costs significantly more, making it suitable primarily for urgent orders or high-value products.

Customs procedures, tariffs, and import duties add complexity and expense to international manufacturing arrangements. These costs vary by product classification, country of origin, and current trade policies. Experienced logistics providers help navigate these requirements and optimize duty classifications to minimize expenses while ensuring compliance with all regulations.

Consolidation services allow smaller publishers to share shipping containers and reduce per-unit transportation costs. These services coordinate multiple shipments from various manufacturers, providing economies of scale typically available only to larger operations. Timing flexibility becomes important when utilizing consolidation services, as departure schedules depend on container fill rates rather than individual customer needs.

Quality Standards and Testing Requirements

Safety Certification and Compliance

Safety testing and certification represent mandatory expenses for most markets, with requirements varying by target demographic and geographic distribution plans. Toy safety standards apply to games intended for younger audiences, while general product safety requirements affect all consumer products. Testing costs typically range from hundreds to thousands of dollars depending on product complexity and certification scope.

Compliance with international safety standards enables broader market access but increases initial certification expenses. European CE marking, American ASTM standards, and Canadian safety requirements each involve separate testing procedures and documentation. Manufacturers experienced in these requirements often provide valuable guidance and coordination services that streamline the certification process.

Ongoing compliance monitoring ensures continued market access and protects against liability issues. Regular production audits and random testing maintain certification validity while identifying potential quality drift before it becomes problematic. These ongoing expenses should be factored into long-term production budgets and pricing strategies.

Quality Assurance Processes

Comprehensive quality control procedures protect brand reputation while minimizing defect-related expenses and customer service issues. Multi-stage inspection processes catch problems early in production when corrections cost less than post-shipping remediation. Investment in quality assurance typically pays for itself through reduced returns, replacements, and customer service expenses.

Statistical sampling methods provide cost-effective quality monitoring while maintaining high confidence levels in overall production quality. These methods balance inspection thoroughness with time and cost constraints, ensuring adequate coverage without excessive overhead. Experienced quality managers adapt sampling rates based on production history and risk assessment.

Third-party inspection services offer independent verification of quality standards, particularly valuable for international manufacturing relationships. These services provide objective assessments and detailed reporting that help maintain consistent quality standards across different production runs and facilities. Investment in independent inspection often proves worthwhile for premium products or critical market launches.

Budgeting and Financial Planning

Cash Flow Management

Manufacturing payments typically require substantial upfront investments, with most facilities requesting deposits ranging from thirty to fifty percent of total order values. Payment schedules vary by manufacturer and order size, but most require full payment before shipping. This payment structure demands careful cash flow planning and adequate working capital reserves.

Crowdfunding platforms have transformed manufacturing finance by enabling pre-sales that fund production costs. Successful campaigns generate sufficient capital to cover manufacturing expenses while building market awareness and customer bases. However, campaign fulfillment requires precise production planning and logistics coordination to meet backer expectations and delivery timelines.

Traditional financing options including business loans, investor funding, and trade credit provide alternative approaches to manufacturing finance. Each option presents distinct advantages and requirements that must align with business objectives and risk tolerance. Professional financial planning helps optimize funding strategies while maintaining operational flexibility.

Cost Estimation and Budgeting

Accurate cost estimation requires detailed understanding of all production components, from raw materials through final packaging and shipping. Comprehensive budgets include manufacturing costs, quality testing, shipping expenses, and contingency allowances for unexpected issues. Professional estimation tools and experienced guidance help ensure budget accuracy and completeness.

Contingency planning addresses potential cost overruns, schedule delays, and quality issues that commonly occur during manufacturing processes. Reserve funds of ten to twenty percent of total production budgets provide protection against unforeseen circumstances while maintaining project viability. These reserves prove especially important for first-time productions where experience levels may not anticipate all potential issues.

Regular budget monitoring throughout production cycles enables early identification of cost variances and corrective action implementation. Tracking actual expenses against budgeted amounts helps refine future estimates while identifying opportunities for cost optimization. This ongoing analysis improves financial planning accuracy for subsequent production runs.

FAQ

What is the typical minimum order quantity for board game manufacturing

Most professional board game manufacturers require minimum orders between 500 to 5000 units, depending on game complexity and production capabilities. Simple card games often have lower minimums around 500-1000 units, while complex games with multiple components may require 2000-5000 units. These minimums help manufacturers achieve cost efficiency and setup cost recovery across production runs.

How much does board game manufacturing typically cost per unit

Per-unit manufacturing costs vary widely based on game complexity, order quantity, and production location, typically ranging from $2 to $15 per unit for most games. Simple card games may cost as little as $1-3 per unit in large quantities, while elaborate games with miniatures and premium components can exceed $20 per unit. Volume discounts significantly reduce per-unit costs, often providing 30-50% savings between minimum and maximum quantity tiers.

What factors most significantly impact manufacturing costs

Component complexity and material quality represent the most significant cost drivers, followed closely by order quantity and manufacturing location. Games requiring custom-shaped pieces, premium materials, or extensive hand assembly incur substantially higher costs than standard productions. Geographic factors including labor rates, material costs, and shipping expenses also significantly influence total manufacturing expenses.

How long does the manufacturing process typically take

Standard board game manufacturing timelines range from 4-12 weeks depending on game complexity, order quantity, and manufacturer capacity. Simple reprints of existing games may complete in 4-6 weeks, while new products requiring tooling setup and quality testing often take 8-12 weeks. International manufacturing adds 2-4 weeks for shipping and customs processing, requiring careful planning around launch dates and market timing requirements.